- The Catalan initiative promotes the search for solutions to control the plastics used in the agri-food sector within the Penedesc regions.

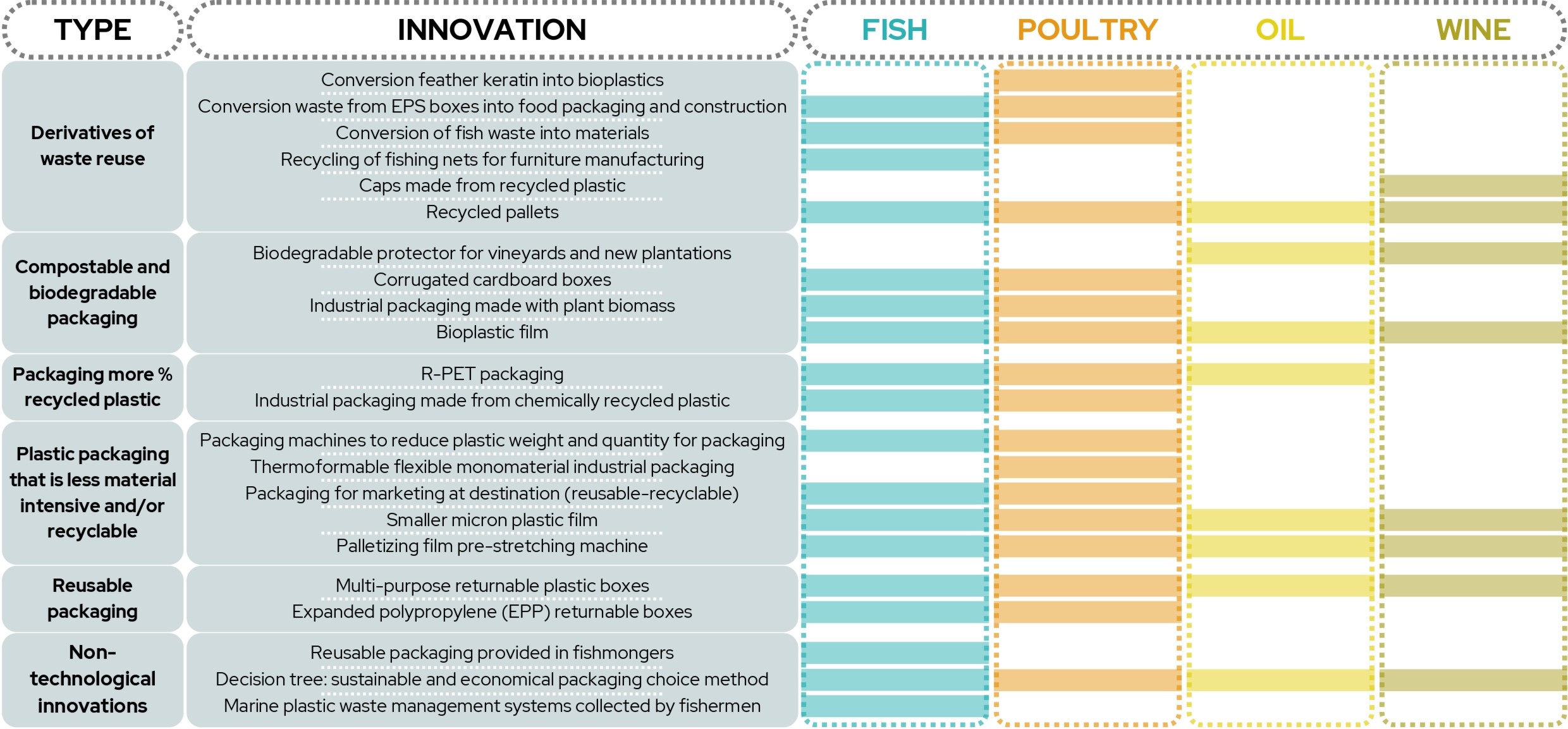

- Following workshops in April and May, the CREDA team has been able to identify a total of 22 innovations applicable to four value chains: oil, wine, fish and poultry.

October 10, 2023

The use of plastics on a day-to-day basis is an unquestionable fact. Over time, we have discovered that it is one of the best materials to make food packaging for different reasons: they allow to see the contents, they lengthen the life of the food and they are more economical. Even so, its massive use is generating an immense amount of waste that cannot be easily disposed of. According to the non-profit organization Ecoember, “plastic can take between 100 and 1.000 years to decompose.”

Faced with this situation, projects such as ECOPAP (Circular Economy per l’Optimitzacio dels Plastics Agroalimentaris del Penedès) arise, which aims to find solutions to develop a more circular and competitive management of plastics within the agri-food sector. Thus, through observation, research and testing of participatory work methodologies with the value chain, teams such as CREDA are identifying and encouraging the application of innovations that can have the same utility as the plastics that have been used so far.

DEVELOPMENT OF THE IDEA

At first, the ECOPAP project focused on four value chains located in the surroundings of the Penedès regions: oil, wine, fish and poultry. With a diagnosis based on the investigation of office and in-depth interviews, it was intended to identify:

- Research and innovation projects that respond to the challenge of circular management of plastics.

- Relevant actors and administrations within the agri-food sector.

- Current use of plastics in value chains.

- Needs of the agri-food sector.

- SWOT analysis of the transferability and added value of solutions: according to needs.

Once the initiative was launched, during the months of April and May, three workshops were organized that followed the ‘world cafe’ methodology, with the aim of bringing together professionals from the sector to dedicate themselves to different activities and to share which ideas or innovations could be most effective in the four value chains.

RESULTS OF THE WORKSHOPS

After listening and sharing thoughts, the CREDA team was able to identify, as the main conclusions of the workshops, a total of 22 innovations that were arranged in a matrix to analyze the applicability of these to the four value chains of the study (access the full version with detailed information on each of the innovations).

Thus, according to characteristics such as the application system or the problem to be solved, ECOPAP researchers have divided the proposals obtained into six categories:

INNOVATIONS FOR WASTE REUSE

1. CIDETEC: the KARMA2020 and UNLOCK projects aim to convert the keratin in bird feathers into materials that can develop bioplastics.

2. VENVIROTECH: this company seeks to take advantage of the organic waste generated in all value chains to manufacture packaging for marketing made of biodegradable polyester.

3. ANAPE, AIMPLAS, ACTECO: the fishing sector uses expanded polyethylene boxes for the transport of products, through the Life EPS SURE project it is intended to transform these boxes into reusable recycled plastic that can be used for food packaging and construction.

4. SCALE and UMORFIL: by converting fish waste into materials, they seek to use fish scales to create building materials and textiles.

5. VINVENTIONS: the Nomacorc Ocean project aims to create caps from recycled plastic that adapt to the physicochemical needs of the products and do not need any type of change.

6. INKA PALETS: this company presents a series of light and resistant pallets that have been made with recycled materials.

REUSABLE PACKAGING

1. TEPSA: this company offers multi-purpose thermoformable plastic boxes that have characteristics to preserve fish and a lower environmental impact.

2. KNAUF INDUSTRIES: its returnable expanded polypropylene (PPE) boxes are also useful for all products that have to maintain the cold chain.

PACKAGING WITH HIGHER % OF RECYCLED PLASTIC

1. KNAUF INDUSTRIES: there are many products that need to maintain the cold chain so as not to lose quality or pose a food problem, the CELOOPS packaging is made with chemically recycled plastic that provides these qualities.

2. VARIOUS (EX. BORGES): creation of final packaging with R-PET as raw material from good recycling management.

PLASTIC PACKAGING THAT IS LESS MATERIAL INTENSIVE AND/OR RECYCLABLE

1. SEALED AIR: this company develops packaging machines that use the Cryovac BDF shrink flow pack system that reduces the weight and amount of plastic in the containers.

2. IRTA, AIMPLAS, PACKAGING CLUSTER, ENPLATER GROUP, EMBOTITS MONELLS: the containers developed by the Soflex project have a lower plastic weight and have a more homogeneous raw material, thus making a more recyclable product that maintains the characteristics of the food.

3. KNAUF INDUSTRIES: the Mitsy project aims to create packaging for marketing at destination that is reusable.

4. CONTROL PACK: packaging with film is a common task in all value chains within the distribution link, so the company develops pre-stretching machines for this film that optimize processes.

5. INNOVI: the cluster, which represents the wine sector, has carried out a study (Visensfilm) that shows how films with less micro-age can be technically and environmentally viable for all agents.

COMPOSTABLE AND BIODEGRADABLE PACKAGING

1. HINOJOSA: the SUMBOX project presents corrugated cardboard boxes that withstand the conditions of cold and heat during the distribution of products.

2. KNAUF INDUSTRIES: NEOPS packaging, seek to offer an alternative made with plant biomass that meets the technical requirements and is recyclable.

3. INNOVI: there is currently a great demand for palletizing film, as it is very useful in the distribution of chains. The cluster seeks to introduce films based on bioplastics that are environmentally viable.

4. BISODISAC: both the vineyards and the new plantations use protectors that help them during their growth, but they are often lost. The company develops biodegradable protective tubes that can be reposted or reused.

NON-TECHNOLOGICAL INNOVATIONS

1. PACKAGING CLUSTER: there are chains that may have greater requirements toward the materials used, so the decision tree methodology is proposed as a way to choose environmentally sustainable and economically viable packaging that are suitable for each option.

2. VARIOUS (XARXES, PESCA NETA, UPCYCLING THE OCEANS, GRAVITY WAVES…): during fishing processes, professionals collect large amounts of marine plastic waste, as a result, various initiatives have emerged that promote the creation of intermediation systems aimed at coordinating and encouraging it.

3. REZERO: the AMBELTEUENVÀS project promotes the use of reusable packaging that will be provided by fishmongers to final consumers at the time of purchase.

WHERE ARE WE GOING?

The innovations, which were exposed to the organizations in charge, arise as a response to the problems that involve issues such as the environment and climate change. However, if we look at the changes in the regulatory framework that regulates the treatment of packaging as plastic waste, it is not only these entities that work to achieve more sustainable value chains.

Currently, in the Spanish territory there are two rules that present a new administrative and economic scenario for companies: (1) Law 7/2022, of 8 April, on Waste and Contaminant Soil for a Circular Economy (LRSCEC), and (2) Royal Decree 1055/22, of 27 December, on Packaging and Packaging Waste (RDERE).

Both regulations seek, mainly, the reduction of the use of plastic, especially virgin, and encourage recycling and reuse. How will they do it? One of the novelties included in the new regulatory framework is a tax on the use of this type of plastic around 0,45€ per kilogram.

ONLINE COMMUNITIES, WE HAVE TO KEEP WORKING

The proposals are designed around the law and the royal decree, even so, they have to work and polish in order to fully include them in the different value chains.

In order to achieve its implementation, the next step of the ECOPAP team is to establish multi-stakeholder thematic communities on its website that allow contact between all parties, such as between producers and developers of an innovation.

Following the example of the innovation matrix, which allows identifying the application of these in more than one value chain, a space will be provided to develop synergies through collaboration and constant feedback between the different agents around the implementation of the innovations.